Kakaretso ea lipoleiti tsa nickel tsa Cryogenic

Lipoleiti tsa nickel tsa Cryogenic li loketse hantle lits'ebetso tse pepesehileng mocheso o tlase haholo. Li sebelisetsoa ho tsamaisa khase ea tlhaho e entsoeng ka metsi (LNG) le khase ea petroleum (LPG).

A 645 Gr A / A 645 Gr B, phokotso ea litšenyehelo le polokeho e eketsehileng kahong ea tanka ea ethylene le LNG.

Mehaho ea morao-rao ea tlhahiso ea lihlahisoa e etsa hore ho khonehe ho rona ho etsa likarolo tse peli tsa tšepe tsa A 645 Gr A le Gr B hammoho le litšepe tse tloaelehileng tsa 5% le 9%.

● LNG

Khase ea tlhaho e qhibilihisoa ka mocheso o tlase haholo oa -164 ° C, e fokotsa molumo oa eona ka karolo ea 600. Sena se etsa hore polokelo ea eona le lipalangoang li khonehe le ho atleha moruong. Lithempereichara tsena tse tlase haholo, tšebeliso ea litšepe tse khethehileng tsa 9% tsa nickel lia hlokahala ho netefatsa hore ho na le ductility e lekaneng le ho hanyetsa ho phatloha ho hoholo. Re fana ka lipoleiti tse pharalletseng karolong ena ea 'maraka, esita le ka botenya ho fihla ho 5 mm.

● LPG

Mokhoa oa LPG o sebelisetsoa ho hlahisa propane le ho sebetsa likhase tse tsoang khase ea tlhaho. Likhase tsena li tšeloa mocheso oa kamore ka khatello e tlase 'me li bolokoa ka litanka tse khethehileng tse entsoeng ka litšepe tsa nickel tse 5%. Re fana ka lipoleiti tsa likhetla, lihlooho le li-cones ho tsoa mohloling o le mong.

Nka ASTM A 645 Gr B Plate Ka mohlala

● Tšebeliso ea A 645 Gr A bakeng sa tlhahiso ea litanka tsa ethylene e fana ka matla a ka bang 15% a phahameng, ts'ireletseho e eketsehileng le monyetla oa ho fokotsa botenya ba lebota bakeng sa ho boloka litšenyehelo tse ngata kahong ea tanka.

● ASTM A 645 Gr B e finyella thepa ea thepa e lekanang le ea litšepe tsa nickel tse tloaelehileng tsa 9% polokelong ea LNG empa e finyella litlhoko tsena ka hoo e ka bang 30% e tlaase ea nickel content. Litholoana tse ling ke ho fokotseha ho hoholo ha litšenyehelo tlhahisong ea litanka tsa LNG tse lebopong le lebopong le kahong ea litanka tsa mafura tsa LNG.

Boleng bo phahameng ka ho fetisisa bakeng sa tekanyo e phahameng ka ho fetisisa ea tšireletso

Motheo oa lipoleiti tsa rona tsa boleng bo holimo tsa nickel ke li-slabs tse hloekileng tse tsoang setsing sa rona sa ho etsa litšepe. Likahare tsa khabone tse tlase haholo li tiisa ho cheseha ho phethahetseng. Melemo e meng e fumaneha ho matla a tšusumetso a sehlahisoa le thepa ea fracturing (CTOD). Sebaka sohle sa poleiti se etsoa tlhahlobo ea ultrasonic. Magnetic e setseng e ka tlase ho 50 Gauss.

Preprocessing ho fihlela litlhoko tse khethehileng tsa bareki

● Ho qhomisoa lehlabathe kapa lehlabathe le ho qhomisoa.

● Tokisetso ea likhahla tse cheselitsoeng: Ho thatafala ho fokolang ha moeli o chesitsoeng ho khoneha ka lebaka la khase e tlaase.

● Ho kobeha poleiti.

Mephato ea tšepe ea li-Cryogenic Nickel Plates Jindalai Can Supply

| Sehlopha sa tšepe | Tekanyetso ea tšepe ea tšepe | Limaraka tsa tšepe |

| 5% litšepe tsa nickel | EN 10028-4 / ASTM/ASME 645 | X12Ni5 A/SA 645 Kereiti A |

| 5.5% litšepe tsa nickel | ASTM/ASME645 | A/SA 645 Sehlopha sa B |

| 9% ea tšepe ea nickel | EN 10028-4 / ASTM/ASME 553 | X7Ni9 A/SA 553 Mofuta oa 1 |

Tlhaloso e qaqileng

-

Nickel 200/201 Nickel Alloy Plate

-

Lisebelisoa tsa Nickel Alloy

-

Letlapa la tšepe la SA387

-

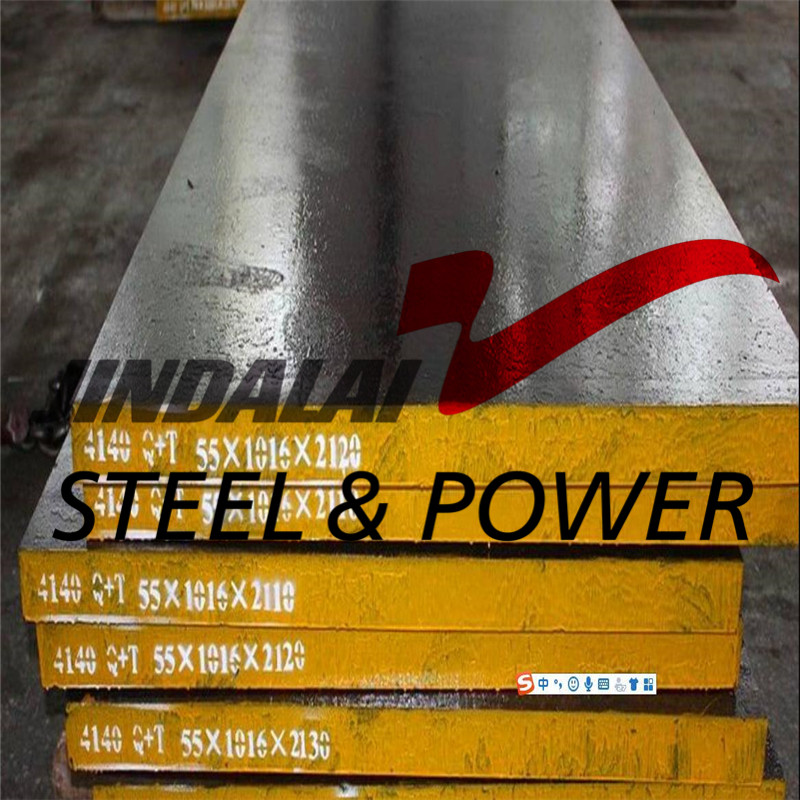

4140 Alloy Steel Plate

-

Plate ea tšepe ea Checkered

-

Corten Grade Weathering Steel Plate

-

Customized Perforated 304 316 Stainless Steel P...

-

Letlapa la Tšepe le Chesitsoeng le Koloitsoeng ka Galvanized

-

Marine Grade CCS Grade A Steel Plate

-

Letlapa la tšepe la AR400

-

Pipeline Steel Plate

-

Letlapa la tšepe la S355G2 Offshore

-

SA516 GR 70 Lipoleiti tsa Tšepe tsa Khatello

-

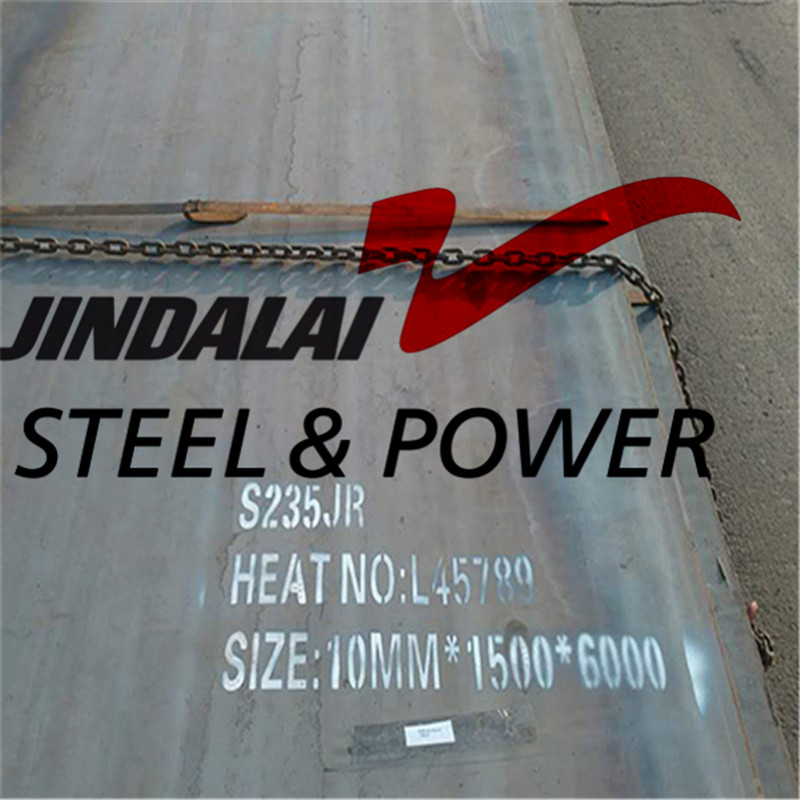

ST37 Steel Plate/ Plate ea Tšepe ea Carbon

-

Lisebelisoa tsa S235JR Carbon Steel / MS Plate