Kakaretso ea Grouting Steel Pipe for Bridge Pile Foundation

Prouting steel pipe ke sesebelisoa sa grouting se sebelisoang haholo masimong a joalo ka meaho, lithanele le boenjiniere ba ka tlas'a lefatše. Mosebetsi oa eona o ka sehloohong ke ho kenya lisebelisoa tsa grouting ka har'a likoti tse ka tlas'a lefatše, ho tlatsa likheo, le ho ntlafatsa matla a ho jara le botsitso ba motheo. Liphaephe tsa grouting li na le melemo ea mohaho o bonolo, kaho e bonolo, le liphello tse kholo, kahoo li 'nile tsa sebelisoa haholo boenjiniere ba ka tlas'a lefatše.

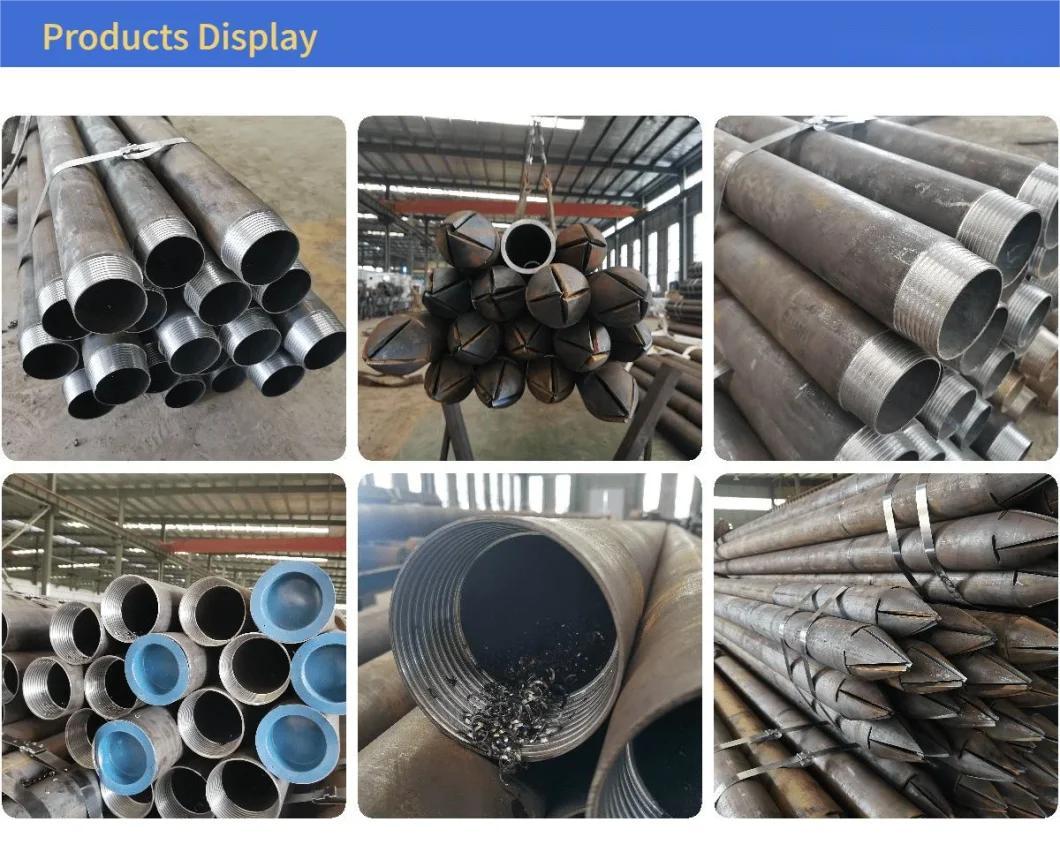

Tlhaloso ea Grouting Steel Pipe bakeng sa Bridge Pile Foundation

| Lebitso la Sehlahiswa | Pipe ea tšepe ea tšepe / liphaephe tsa tšepe / phala ea tšepe ea grouting / geology ea ho phunya / pompo ea subgrade / micro pile. |

| Litekanyetso | GB/T 9808-2008, API 5CT, ISO |

| Mephato | DZ40, DZ60, DZ80, R780, J55, K55, N80, L80, P110, 37Mn5, 36Mn2V, 13Cr, 30CrMo, A106 B, A53 B, ST52-4 |

| Ka ntle bophara | 60mm-178mm |

| Botenya | 4.5-20 limilimithara |

| Bolelele | 1-12M |

| Ho kobeha ho lumelletsoe | Ha e fete 1.5mm/m |

| Mokhoa oa Ts'ebetso | Beveling/Screening/Ho phunya lesoba/Ho thapolla ha banna/Ho roka ka Basali/Khoele ea Trapezoidal/Ho supa |

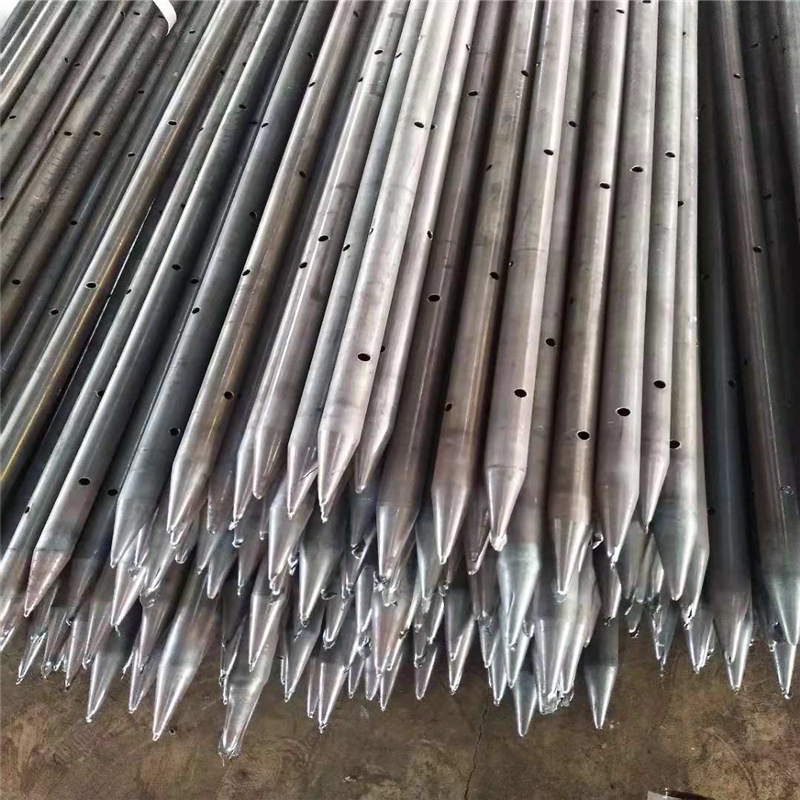

| Ho paka | Ho roala ha banna le ba batšehali ho tla sireletsoa ka liaparo tsa polasetiki kapa likatiba tsa polasetiki Liphaephe tsa pointer li tla be li se na letho kapa joalo ka kopo ea moreki. |

| Kopo | Kaho ea Litsela tse kholo/Kaho ea Metro/Kaho ea Borokho/Projeke ea ho Tiisa 'Mele oa Thaba /Tunnel Portal/Deep Foundation/Underpinning jj. |

| Nako ea ho romella | Ka likepe tse ngata ka bongata bo fetang lithane tse 100, Ka tlase ho otara ea lithane tse 100, e tla kenngoa ka har'a lijana, Bakeng sa odara e ka tlase ho lithane tse 5, hangata re khetha setshelo sa LCL (ka tlase ho sejana), ho boloka litšenyehelo bakeng sa moreki. |

| Boema-kepe ba likepe | Qingdao port, kapa boema-kepe ba Tianjin |

| Nako ea khoebo | CIF, CFR, FOB, EXW |

| Nako ea ho lefa | 30% TT + 70% TT khahlanong le kopi ea B/L, kapa 30%TT + 70% LC. |

Pipe ea tšepe ea Grouting e sebelisoang ka tloaelo e nang le Kereiti

| Kereiti | C . | Si | Mong. | P, S | Cu | Ni | Mo | Cr |

| 10 | 0.07-0.14 | 0.17-0.37 | 0.35-0,65 | Boholo.0.035 | Max.0.25 | Max.0.25 | / | Max.0.15 |

| 20 | 0.17-0.24 | 0.17-0.37 | 0.35-0,65 | Boholo.0.035 | Boholo.0.025 | Max.0.25 | / | Max.0.25 |

| 35 | 0.32-0,40 | 0.17-0.37 | 0.50-0,80 | Boholo.0.035 | Max.0.25 | Max.0.25 | Max.0.25 | |

| 45 | 0.42-0,50 | 0.17-0.37 | 0.50-0,80 | Boholo.0.035 | Max.0.25 | Max.0.25 | Max.0.25 | |

| 16Mn | 0.12-0.20 | 0.20-0,55 | 1.20-1.60 | Boholo.0.035 | Max.0.25 | Max.0.25 | Max.0.25 | |

| 12Crmo | 0.08-0.15 | 0.17-0.37 | 0.40-0,70 | Boholo.0.035 | Max.0.25 | Max.0.30 | 0.40-0,55 | 0.40-0,70 |

| 15Crmo | 0.12-0.18 | 0.17-0.37 | 0.40-0,70 | Boholo.0.035 | Max.0.25 | Max.0.30 | 0.40-0,55 | 0.80-1.10 |

| 12Cr1Mov | 0.08-0.15 | 0.17-0.37 | 0.40-0,70 | Boholo.0.035 | Max.0.25 | Max.0.30 | 0.25-0,35 | 0.90-1.20 |

Thepa ea Mechini

| Kereiti | Matla a thata (Mpa) | Ho hlahisa matla(Mpa) | Elongation(%) |

| 10 | ≥335 | ≥205 | ≥24 |

| 20 | ≥390 | ≥245 | ≥20 |

| 35 | ≥510 | ≥305 | ≥17 |

| 45 | ≥590 | ≥335 | ≥14 |

| 16Mn | ≥490 | ≥325 | ≥21 |

| 12CrMo | ≥410 | ≥265 | ≥24 |

| 15CrMo | ≥440 | ≥295 | ≥22 |

| 12Cr1MoV | ≥490 | ≥245 | ≥22 |

Tšebeliso ea lipeipi tsa tšepe tsa grouting

Pipe ea tšepe ea tšepe ke lisebelisoa tse sebelisoang hangata liphaepheng, tse sebelisoang haholo liindastering, ho boloka metsi, ho haha, ho sireletsa mollo le masimo a mang. E na le khanyetso e ntle ea kutu, 'me e na le matla a itseng a khatello.

Liphaephe tsa tšepe tsa tšepe hangata li entsoe ka tšepe e sa hloekang, kahoo li na le khanyetso e ntle ea kutu. Ho phaella moo, phala ea tšepe ea grouting e boetse e na le matla a itseng a hatellang 'me e khona ho mamella tekanyo e itseng ea khatello. Ho phaella moo, pipe ea tšepe ea grouting e boetse e na le ho hanyetsa ho apara 'me e ka sebelisoa nako e telele.

-

A106 Crosshole Sonic Logging Welded Tube

-

Steel Round Bar / Steel Rod

-

ASTM A106 Mophato oa B Pipe e Seamless

-

A106 GrB Seamless Grouting Liphaephe tsa tšepe bakeng sa qubu

-

Pipe ea tšepe ea A53 Grouting

-

Hollow Grouting Spiral Anchor Rod Steel R32

-

R25 Self-Drilling Hollow Grout Anchor...

-

ASTM A312 Pipe ea tšepe e sa tsitsang