1. Mohato oa Pele: Ho qhibilihisa

Aluminium e etsoa ka ho sebelisa electrolysis ka tekanyo ea indasteri 'me lisebelisoa tsa aluminium li hloka matla a mangata hore li sebetse hantle. Hangata li-smelters li lula li le haufi le lifeme tse kholo tsa motlakase ka lebaka la tlhoko ea tsona ea matla. Keketseho leha e le efe ea theko ea matla, kapa boholo ba matla a hlokahalang ho hloekisa aluminium ho ea boemong bo phahameng, ho eketsa litšenyehelo tsa likhoele tsa aluminium. Ho phaella moo, aluminium e qhibilihisitsoeng e arohana 'me e ea sebakeng sa pokello. Mokhoa ona o boetse o na le litlhoko tse ngata tsa matla, tse amang le litheko tsa 'maraka oa aluminium.

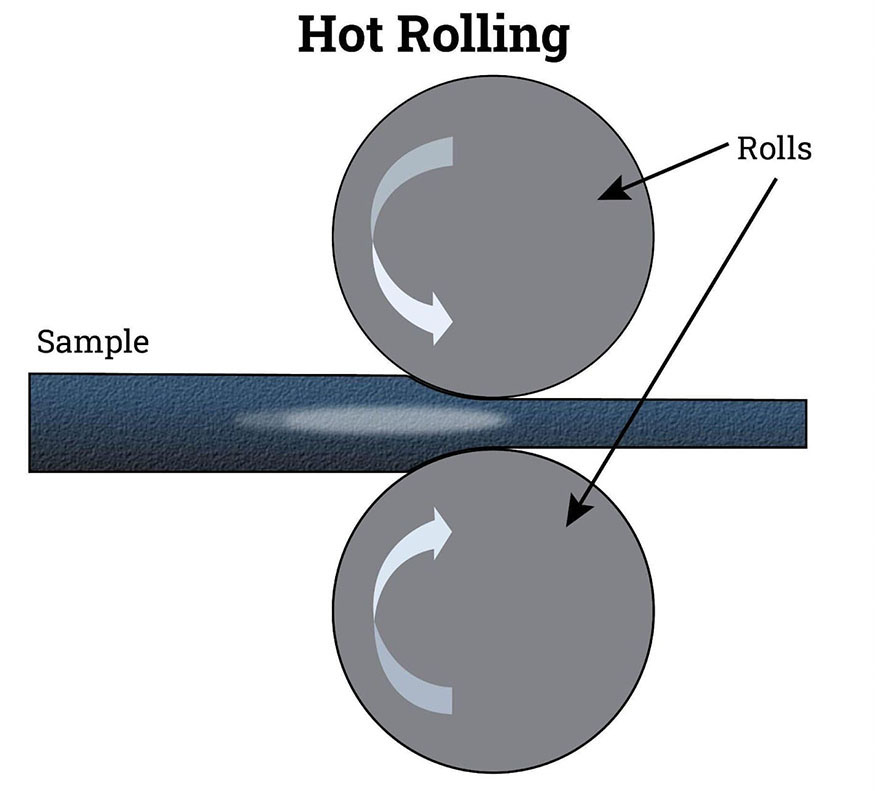

2. Mohato oa Bobeli: Hot Rolling

Ho roala ho chesang ke e 'ngoe ea litsela tse atisang ho sebelisoa ho fokotsa letlapa la aluminium. Ha ho chesa, tšepe e futhumatsoa ka holim'a ntlha ea recrystallization ho holofatsa le ho e bopa ho ea pele. Joale, tšepe ena ea tšepe e fetisoa ka lipara tse le 'ngoe kapa ho feta tsa meqolo. Sena se etsoa ho fokotsa botenya, ho etsa hore botenya bo tšoane, le ho finyella boleng bo lakatsehang ba mochine. Coil ea aluminium e entsoe ka ho sebetsa lakane ka likhato tse 1700 tsa Fahrenheit.

Mokhoa ona o ka hlahisa libopeho tse nang le li-parameter tse loketseng tsa geometri le litšobotsi tsa thepa ha u ntse u boloka molumo oa tšepe o sa fetohe. Ts'ebetso ena e bohlokoa ho hlahiseng lintho tse seng li felile le tse felileng, joalo ka lipoleiti le maqephe. Leha ho le joalo, lihlahisoa tse phethiloeng li fapane le li-coil tse pholileng tse batang, tse tla hlalosoa ka tlase, ka hore li na le botenya bo fokolang ka lebaka la lithōle tse nyenyane tse holim'a metsi.

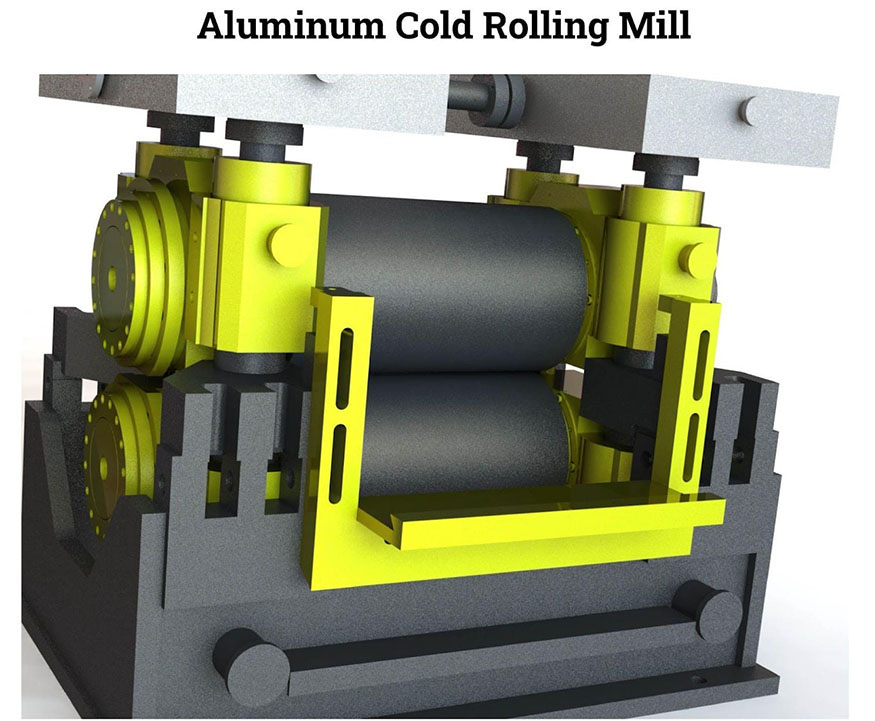

3. Mohato oa Boraro: Cold Rolling

Cold rolling ea marapo a tšepe ke sebaka se ikhethang sa indasteri ea tšepe. Ts'ebetso ea "mohatsela o batang" e kenyelletsa ho kenya aluminium ka har'a lirolara ka mocheso o tlase ho feta mocheso oa eona oa recrystallization. Ho penya le ho hatella tšepe ho eketsa matla a eona a lihlahisoa le ho ba thata. Cold rolling etsahala ka mosebetsi-hardening thempereichara (mocheso ka tlaase ho lintho tse bonahalang recrystallization mocheso), 'me chesang rolling etsahala ka holim'a mosebetsi thatafatsa mocheso- ena ke phapang pakeng tsa ho bidikang hot le serame rolling.

Liindasteri tse ngata li sebelisa mokhoa oa ho phekola ka tšepe o tsejoang ka hore ke ho roala ho batang ho hlahisa lesela le tšepe le nang le gauge ea ho qetela e lakatsehang. Hangata meqolo e futhumatsoa ho thusa aluminium hore e sebetse haholoanyane, 'me lubricant e sebelisetsoa ho thibela lesela la aluminium ho khomarela meqolo. Bakeng sa ho lokisa hantle, motsamao oa lirolo le mocheso li ka fetoloa. Lesela la aluminium, le seng le ntse le kolobisoa ka mocheso o chesang, le mekhoa e meng, ho kenyelletsa le ho hloekisa le ho alafa, le pholile ho fihlela mocheso oa kamore pele le kenngoa mocheng o batang oa leloala indastering ea aluminium. Aluminium e hloekisoa ka ho e hlatsoa ka sesepa 'me phekolo ena e etsa hore khola ea aluminium e be thata ho lekana ho mamella ho bilika ha serame.

Ka mor'a hore mehato ena ea boitokisetso e rarolloe, li-strips li feta khafetsa ka li-roller, butle-butle li lahleheloa ke botenya. Lifofane tsa lithapo tsa tšepe li ferekanngoa 'me li behiloe ho pholletsa le ts'ebetso, e leng se hlahisang sehlahisoa sa ho qetela se thata, se matla haholoanyane. Cold rolling ke e 'ngoe ea mekhoa e tsebahalang haholo ea ho thatafatsa aluminium hobane e fokotsa botenya ba aluminium ha e ntse e pshatleha le ho sututsoa ka lirolara. Mokhoa oa ho roala o batang o ka theola botenya ba khoele ea aluminium ka ho fihla ho 0.15 mm.

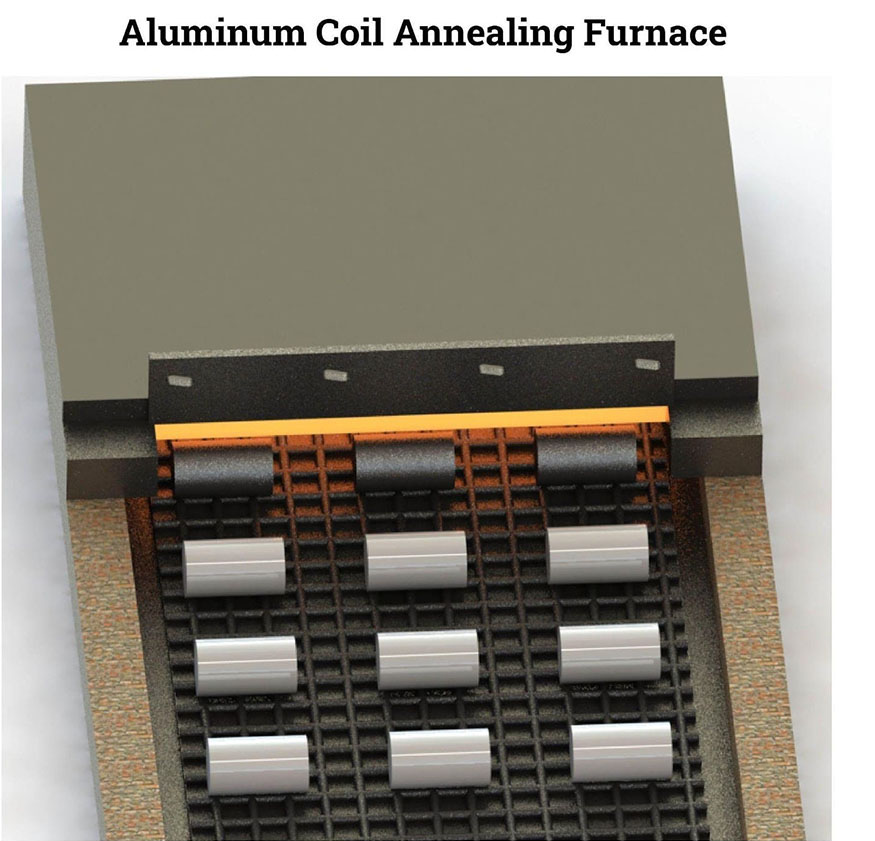

4. Mohato oa bone: Annealing

Ts'ebetso ea annealing ke phekolo ea mocheso e sebelisoang haholo-holo ho etsa hore thepa e bonolo le e fokolang. Ho fokotseha ha li-dislocation tsa sebopeho sa kristale sa thepa e ntseng e ts'oaroa ho baka phetoho ena ea ho thatafala le ho feto-fetoha ha maemo. Ho qoba ho hloleha ho brittle kapa ho etsa hore thepa e sebetse haholoanyane bakeng sa ts'ebetso e latelang, annealing e etsoa khafetsa ka mor'a hore thepa e sebetse ka thata kapa e batang.

Ka ho tsosolosa ka katleho sebopeho sa lijo-thollo tsa kristale, annealing e tsosolosa lifofane tse thellang 'me e nolofalletsa ho bōpa karolo e eketsehileng ntle le matla a feteletseng. Motsoako oa aluminium o thatafalitsoeng ke mosebetsi o tlameha ho futhumatsoa ho mocheso o itseng o pakeng tsa 570 ° F le 770 ° F bakeng sa nako e reriloeng esale pele, ho tloha metsotso e ka bang mashome a mararo ho isa ho lihora tse tharo. Boholo ba karolo e ntseng e ts'oaroa le motsoako oo e entsoeng ka oona ho khetholla mocheso le litlhoko tsa nako, ka ho latellana.

Annealing e boetse e tsitsisa litekanyo tsa karolo, e felisa mathata a tlisoang ke mathata a ka hare, 'me e fokotsa khatello ea kelello e ka 'nang ea hlaha, ka karolo e itseng, nakong ea mekhoa e kang ho fereka kapa ho lahla. Ho feta moo, li-alloys tsa aluminium tse sa phekoleheng mocheso le tsona li ka ts'oaroa ka katleho. Ka hona, hangata e sebelisoa ho li-cast, extruded, kapa likarolo tsa aluminium tse entsoeng.

Bokhoni ba thepa ea ho bopeha bo matlafatsoa ke ho anneal. Ho hatella kapa ho kobeha ka thata, lisebelisoa tse brittle li ka ba phephetso ntle le ho baka ho robeha. Anealing lithuso ho tlosa kotsi ena. Ho feta moo, ho ikoetlisa ho ka eketsa ts'ebetso. Ho brittle ho feteletseng ha lesela ho ka etsa hore lisebelisoa li senyehe haholo. Ka annealing, ho thatafala ha thepa ho ka fokotsoa, e leng ho ka fokotsang ho roala ha lisebelisoa. Mathata leha e le afe a setseng a felisitsoe ke annealing. Hangata ho molemo ho fokotsa tsitsipano e setseng kae kapa kae moo ho ka khonehang hobane e ka baka mapetsong le mathata a mang a mochine.

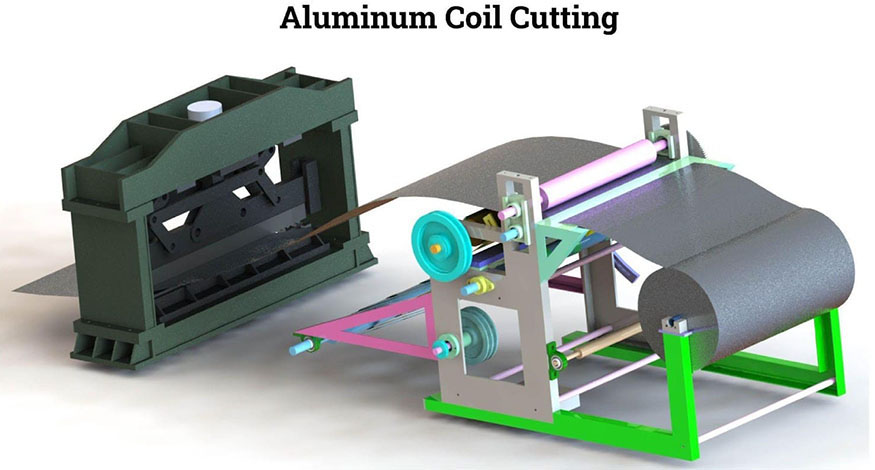

5. Mohato oa Bohlano: Ho Slitting le Ho Seha

Likhoeli tsa aluminium li ne li ka etsoa ka moqolo o le mong o telele o sa khaotseng. Leha ho le joalo, ho kenya coil ka har'a meqolo e menyenyane, e hloka ho khaoloa. Ho etsa mosebetsi ona, lirolo tsa aluminium li tsamaisoa ka har'a lisebelisoa tse sehang moo mahare a hlabang ka mokhoa o makatsang a etsang likoto tse nepahetseng. Ho hlokahala matla a mangata ho etsa opereishene ena. Li-slitters li arola moqolo likotoana tse nyane ha matla a sebelisitsoeng a feta matla a aluminium.

Ho qala ts'ebetso ea ho slitting, aluminium e kenngoa ka har'a sesebelisoa sa uncoiler. Ka mor'a moo, e fetisoa ka sete ea lithipa tse rotary. Li-blades li behiloe ho fumana moeli o motle ka ho fetisisa, ho nahanoa ka bophara bo lakatsehang le tumello. Ho tsamaisa thepa e sehiloeng ho recoiler, ka mor'a moo thepa e feptjoa ka li-separators. Joale aluminiamo e ea bokelloa ebe e phutheloa ka khoele ho itokisetsa ho romelloa.

Jindalai Steel Group ke Khamphani e Eteletseng Pele ea Aluminium ebile e fana ka Coil/sheet/plate/strip/pipe/foil. Re na le moreki ea tsoang Philippines, Thane, Mexico, Turkey, Pakistan, Oman, Israel, Egypt, Arab, Vietnam, Myanmar, India joalo-joalo Romela lipotso tsa hau mme re tla thabela ho buisana le uena ka botsebi.

HOTLINE:+86 18864971774WECHAT: +86 18864971774WHATSAPP:https://wa.me/8618864971774

EMAIL:jindalaisteel@gmail.com sales@jindalaisteelgroup.com WEBSITE:www.jindalaisteel.com

Nako ea poso: Dec-19-2022