Koporo

Tšebeliso ea koporo le koporo e qalile makholong a lilemo, 'me kajeno e sebelisoa ho tse ling tsa mahlale a morao-rao le lits'ebetso ha e ntse e sebelisoa ke lits'ebetso tsa setso joalo ka liletsa tsa mmino, li-eyelets tsa koporo, lingoliloeng tsa mekhabiso le lisebelisoa tsa pompo le mamati.

Brass e Entsoe ka Eng?

Brass ke motsoako o entsoeng ka motsoako oa koporo le zinki ho hlahisa lisebelisoa tse nang le mefuta e mengata ea tšebeliso ea boenjiniere. Sebopeho sa koporo se fa tšepe sebaka sa ho qhibiliha se loketseng lits'ebetso tse ngata, ho kenyelletsa le tse loketseng ho kopanya ho sebelisa mokhoa oa brazing. Sebaka se qhibilihang sa koporo se tlase ho feta koporo hoo e ka bang likhato tse 920 ~ 970 tsa Celsius ho latela palo ea tlatsetso ea Zn. Sebaka se qhibilihang sa koporo se tlase ho feta sa koporo ka lebaka la Zn e ekelitsoeng. Li-alloys tsa koporo li ka fapana ka sebopeho sa Zn ho tloha ho tse nyane joalo ka 5% (tseo hangata li bitsoang Gilding Metals) ho ea ho tse fetang 40% joalo ka ha li sebelisoa mecheng ea machining brasses. Lentsoe le sa tloaelehang le sebelisoang ke boronse ba koporo, moo ho sebelisoang litlatsetso tse ling tsa thini.

Koporo e sebelisetsoa eng?

Ho hlophisoa ha koporo le ho eketsoa ha zinki ho koporo ho phahamisa matla le ho fana ka mefuta e mengata ea litšoaneleho, e leng se etsang hore li-brass e be lisebelisoa tse ngata tse fapaneng haholo. Li sebelisetsoa matla a tsona, ho hanyetsa ho bola, ponahalo le 'mala, le boiketlo ba ho sebetsa le ho kopanya. Mekhahlelo e le 'ngoe ea li-alpha brasses, e nang le hoo e ka bang 37% ea Zn, e na le ductile haholo ebile e bonolo ho sebetsa ka mokhoa o batang, e cheselletsang le ea braze. Li-brasses tsa alpha-beta tsa mekhahlelo e 'meli hangata li chesa haholo.

Na ho na le moetso o fetang o le mong oa koporo?

Ho na le li-brass tse ngata tse nang le libopeho tse fapaneng le litšoaneleho tse etselitsoeng lits'ebetso tse ikhethileng ka boemo ba ho eketsoa ha zinki. Maemo a tlase a tlatsetso ea Zn hangata a bitsoa Guilding Metal kapa Red Brass. Ha maemo a holimo a Zn e le li-alloys tse kang Cartridge Brass, Free Machining Brass, Naval Brass. Li-brasses tsena tsa morao li boetse li na le tlatsetso ea likarolo tse ling. Ho eketsoa ha lead ho koporo ho 'nile ha sebelisoa ka lilemo tse ngata ho thusa machinability ea thepa ka ho kenya lintlha tsa chip break. Ha kotsi le likotsi tsa loto li lemohuoa haufinyane tjena li nketsoe sebaka ke lintho tse kang silicon le bismuth ho fihlela tšobotsi e tšoanang ea machining. Tsena joale li tsejoa e le li-lead tse tlase kapa li-brasses tsa mahala.

Na likarolo tse ling li ka eketsoa?

Ee, likarolo tse nyane tsa likarolo tse ling tsa alloying le tsona li ka kenyelletsoa koporo le koporo. Mehlala ea Commons ke lead bakeng sa bokhoni ba mochini joalo ka ha ho boletsoe ka holimo, empa hape le arsenic bakeng sa ho hanyetsa kutu ho dezincification, tin bakeng sa matla le ho bola.

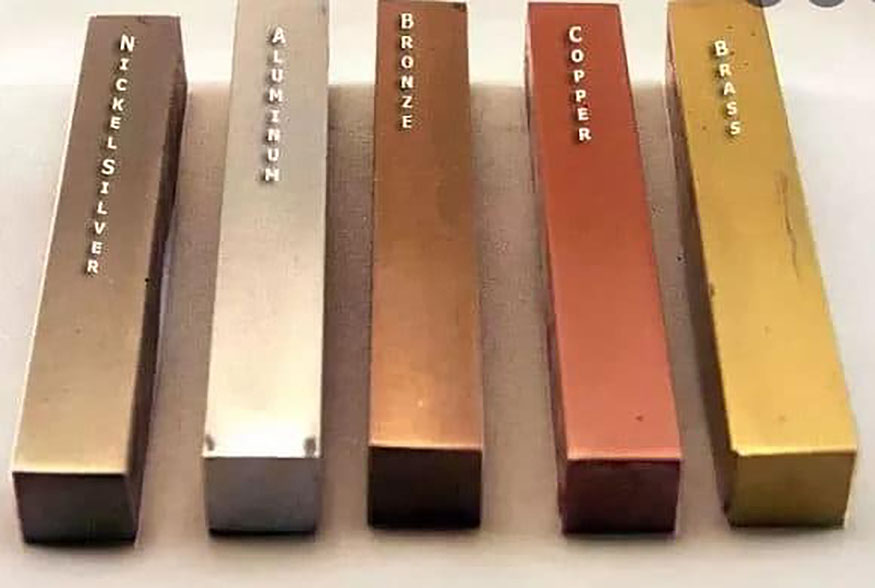

Mmala oa Koporo

Ha lihlahisoa tsa zinki li ntse li eketseha, 'mala oa fetoha. Li-alloys tse tlase tsa Zn hangata li ka tšoana le koporo ka 'mala, ha li-alloys tse phahameng tsa zinki li hlaha khauta kapa mosehla.

Sebopeho sa Lik'hemik'hale

AS2738.2 -1984 Litlhaloso tse ling tse batlang li lekana

| Nomoro ea UNS | JOALOKAHA No | Lebitso le Tloaelehileng | Nomoro ea BSI | Nomoro ea ISO | Nomoro ea JIS | Koporo % | Zinc % | Ketapele % | Tse ling % |

| C21000 | 210 | 95/5 Gilding Metal | - | CuZn5 | C2100 | 94.0-96.0 | ~ 5 | <0.03 | |

| C22000 | 220 | 90/10 Gilding Metal | CZ101 | CuZn10 | C2200 | 89.0-91.0 | ~ 10 | <0.05 | |

| C23000 | 230 | 85/15 Gilding Metal | CZ102 | CuZn15 | C2300 | 84.0-86.0 | ~ 15 | <0.05 | |

| C24000 | 240 | 80/20 Gilding Metal | CZ103 | CuZn20 | C2400 | 78.5-81,5 | ~ 20 | <0.05 | |

| C26130 | 259 | 70/30 Arsenical Brass | CZ126 | CuZn30As | ~C4430 | 69.0-71.0 | ~ 30 | <0.07 | Arsenic 0.02-0.06 |

| C26000 | 260 | 70/30 Brass | CZ106 | CuZn30 | C2600 | 68.5-71.5 | ~ 30 | <0.05 | |

| C26800 | 268 | Borose bo Bosehla (65/35) | CZ107 | CuZn33 | C2680 | 64.0-68.5 | ~ 33 | <0.15 | |

| C27000 | 270 | 65/35 Wire Brass | CZ107 | CuZn35 | - | 63.0-68.5 | ~ 35 | <0.10 | |

| C27200 | 272 | 63/37 Brass e Tloaelehileng | CZ108 | CuZn37 | C2720 | 62.0-65.0 | ~ 37 | <0.07 | |

| C35600 | 356 | Brass e Behang, 2% e etellang pele | - | CuZn39Pb2 | C3560 | 59.0-64.5 | ~ 39 | 2.0-3.0 | |

| C37000 | 370 | Brass e Behang, 1% e etellang pele | - | CuZn39Pb1 | ~C3710 | 59.0-62.0 | ~ 39 | 0.9-1.4 | |

| C38000 | 380 | Karolo ea Brass | CZ121 | CuZn43Pb3 | - | 55.0-60.0 | ~ 43 | 1.5-3.0 | Aluminium 0.10-0.6 |

| C38500 | 385 | Brass e Sehang mahala | CZ121 | CuZn39Pb3 | - | 56.0-60.0 | ~ 39 | 2.5-4.5 |

Hangata li-brasses li sebelisoa bakeng sa ponahalo ea tsona

| Nomoro ea UNS | Lebitso le Tloaelehileng | Mmala |

| C11000 | ETP Koporo | Pinki e Bonolo |

| C21000 | 95/5 Gilding Metal | Red Brown |

| C22000 | 90/10 Gilding Metal | Khauta ea Boronse |

| C23000 | 85/15 Gilding Metal | Khauta ea Tan |

| C26000 | 70/30 Brass | Khauta e tala |

Gilding Metal

C22000, 90/10 Gilding tšepe, e kopanya 'mala o motle oa khauta le motsoako o motle ka ho fetisisa oa matla, ductility le ho hanyetsa kutu ea li-alloys tsa thota tsa Cu-Zn. E na le boemo ba leholimo ho fihlela 'mala o nonneng oa boronse. E na le bokhoni bo botle ba ho taka bo tebileng, 'me e hanana le ho bola ha maemo a leholimo a matla le tikoloho ea metsi. E sebelisoa ho li-fascias tsa meralo, mabenyane, mekhabiso ea mekhabiso, lithupa tsa mamati, li-escutcheons, lisebelisoa tsa marine.

Li-brasses tse mosehla

C26000, 70/30 Brass le C26130, Arsenical brass, li na le ductility le matla a babatsehang, 'me ke tsona tse sebelisoang ka ho fetisisa. Arsenic brass e na le tlatsetso e nyane ea arsenic, e ntlafatsang haholo ho hanyetsa kutu ka metsing, empa ka tsela e 'ngoe e ts'oana hantle. Li-alloys tsena li na le 'mala o mosehla o khanyang oo hangata o amanang le koporo. Li na le motsoako o nepahetseng oa matla le ductility ka har'a li-alloys tsa Cu-Zn, hammoho le khanyetso e ntle ea kutu. C26000 e sebelisoa bakeng sa meralo ea kaho, lijana le libopeho tse ohliloeng, liteishene tsa motlakase le likhokahano, maoara a mamati le lisebelisoa tsa liphaephe. C26130 e sebelisetsoa li-tube le lisebelisoa tse amanang le metsi, ho kenyeletsoa metsi a nooang.

C26800, Yellow brass, ke karolo e le 'ngoe ea alpha brass e nang le koporo e tlase haholo. E sebelisoa moo thepa ea eona e tebileng ea ho taka le litšenyehelo tse tlase li fanang ka monyetla. Ha likaroloana tse cheselitsoeng tsa mohato oa beta li ka theha, ho fokotsa ductility le ho hanyetsa kutu.

Brasses e nang le likarolo tse ling

C35600 le C37000, koporo e betliloeng, ke li-alpha-beta tse 60/40 tse nang le maemo a fapaneng a loto a kentsoeng ho fana ka litšobotsi tsa mahala tsa mochini. Li sebelisoa haholo bakeng sa lipoleiti tse betliloeng le li-plaque, lisebelisoa tsa lihahi, lisebelisoa. Ha lia lokela ho sebelisoa bakeng sa mosebetsi o nang le asiti, eo li-alpha brasses tsa karolo e le 'ngoe li lokelang ho sebelisoa.

C38000, Section brass, ke koporo e etellang pele ea alpha/beta habonolo e nang le tlatsetso e nyane ea aluminium, e fanang ka 'mala o khanyang oa khauta. Moetapele o fana ka litšobotsi tsa ho itšeha mahala. C38000 e fumaneha e le lithupa tse fetisitsoeng, likanale, lifolete le li-angles, tseo hangata li sebelisoang ho lisebelisoa tsa lihahi.

C38500, koporo e sehang, ke mofuta o ntlafalitsoeng haholo oa 60/40 oa koporo, o nang le litšobotsi tse ntle haholo tsa ho seha mahala. E sebelisoa tlhahisong ea bongata ba likarolo tsa koporo moo ho hlokahalang tlhahiso e ngata le bophelo bo bolelele ba lisebelisoa, 'me moo ho sa hlokeng ho etsoa ha serame ka mor'a ho sebetsa.

Lethathamo la Lihlahisoa tsa Brass

● Foromo ea Sehlahisoa

● Lihlahisoa tse bataletseng

● Lithupa tse betliloeng, litšepe le likarolo

● Ho qhekella li-stock & forgings

● Li-tubes tse se nang moroallo bakeng sa lisebelisoa tsa mocheso

● Li-tubes tse se nang moroallo bakeng sa ho futhumatsa moea le ho etsa sehatsetsi

● Li-tubes tse se nang moroallo bakeng sa merero ea boenjiniere

● Mohala bakeng sa merero ea boenjiniere

● Mohala o sebelisetsoang motlakase

Sehlopha sa Jindalai Steel se fana ka lihlahisoa tse fapaneng tsa koporo ka boholo le bongata ho fihlela litlhoko tsa morero ofe kapa ofe. Re boetse re amohela mekhoa, boholo, libopeho le mebala. Romela potso ea hau mme re tla thabela ho buisana le uena ka botsebi.

HOTLINE:+86 18864971774WECHAT: +86 18864971774WHATSAPP:https://wa.me/8618864971774

EMAIL:jindalaisteel@gmail.com sales@jindalaisteelgroup.com WEBSITE:www.jindalaisteel.com

Nako ea poso: Dec-19-2022