Kakaretso

304 tšepe e sa hloekang ke mofuta oa lisebelisoa tsa tšepe tse sa hloekang, ho hanyetsa mafome ho matla ho feta 200 letoto la lisebelisoa tsa tšepe tse sa hloekang, mocheso o phahameng oa ho hanyetsa mocheso o boetse o molemo, o ka ba likhato tse 1000-1200. 304 tšepe e sa hloekang e na le khanyetso e ntle ea kutu le ho hanyetsa kutu pakeng tsa lijo-thollo. 304 tšepe e sa hloekang e na le khanyetso e matla ea kutu. E boetse e na le khanyetso e ntle ea kutu ho tharollo ea alkaline le li-acid tse ngata tsa organic le inorganic.

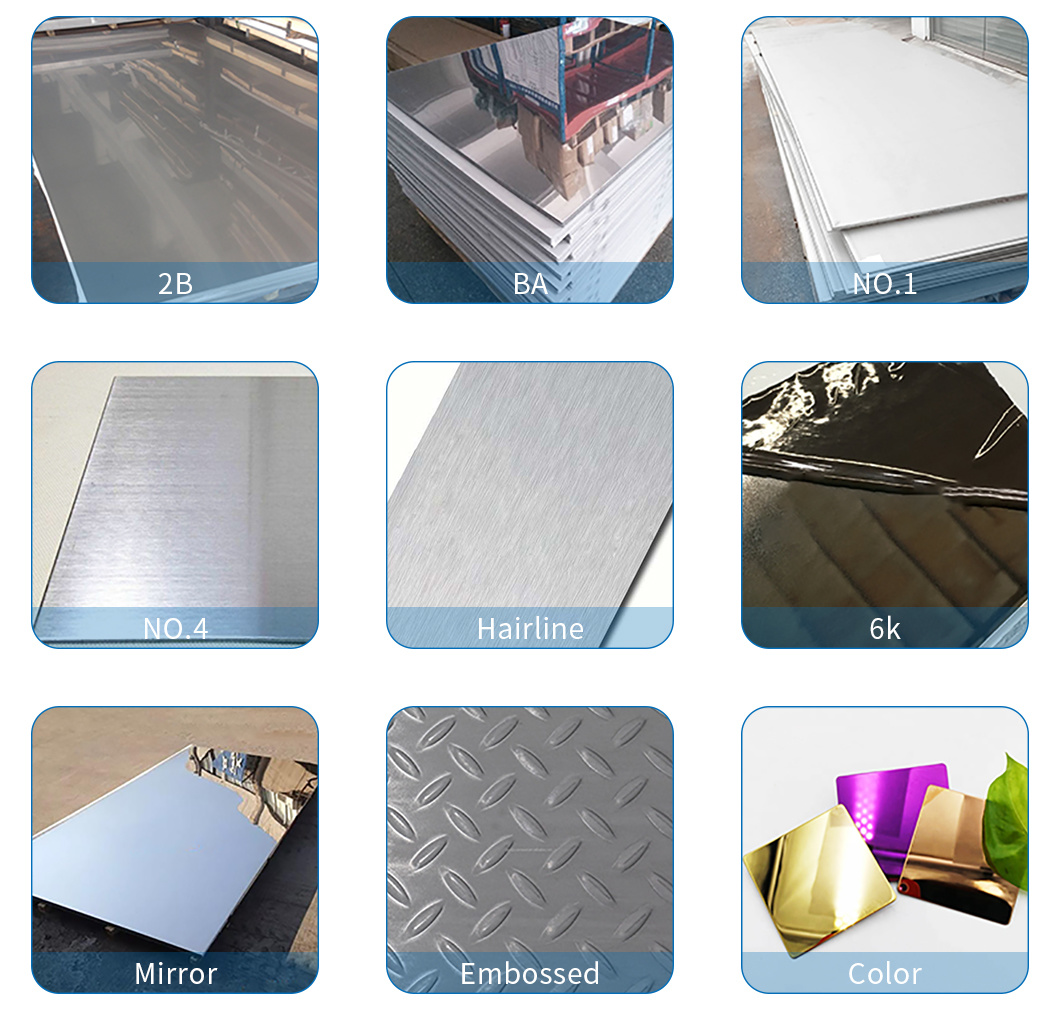

Tlhaloso

| Surface Finish | Tlhaloso |

| 2B | Qetello e khanyang, ka mor'a ho phalla ha serame, ka phekolo ea mocheso, e ka sebelisoa ka ho toba, kapa e le mohato oa pele oa ho polishing. |

| 2D | Sebaka se lerootho, se bakoang ke serame se pota-potileng se lateloa ke ho phunya le ho theoha. E ka 'na ea fumana moqolo oa ho qetela oa leseli ka har'a meqolo e sa pholisoang. |

| BA | Qetello e khanyang ea Annealed e fumanoang ka ho kenya thepa ka tlas'a sepakapaka e le hore sekala se se ke sa hlahisoa ka holim'a metsi. |

| No.1 | Qetello e mahoashe, e lerootho, e hlahisoang ke ho chesa ho ea ho botenya bo boletsoeng. E lateloe ke annealing le descaling. |

| No.3 | Qeto ena e bentšitsoe ka No.100 ho ea ho No.120 abrasive e boletsoeng ho JIS R6001. |

| No.4 | Qeto ena e bentšitsoe ka No.150 ho ea ho No.180 abrasive e boletsoeng ho JIS R6001. |

| Mohala oa moriri | Qetello e ntle, e sirelelitsoeng ke filimi ea PVC pele e sebelisoa, e sebelisoa ka kitchenware, |

| Seipone sa 8K | "8" ho 8K e bolela karolo ea likarolo tsa alloy (304 tšepe e sa hloekang haholo-holo e bua ka litaba tsa likarolo), "K" e bolela boemo ba ho bonahatsa ka mor'a ho belisoa. Sebaka sa seipone sa 8K ke boemo ba seipone ba bokaholimo bo bonts'itsoeng ke tšepe ea chrome nickel alloy. |

| E khabisitsoe | Lipampiri tse entsoeng ka tšepe tse sa hloekang ke lisebelisoa tse feto-fetohang tse sebelisetsoang ho etsa mokhabiso holim'a tšepe. Ke khetho e ntle haholo bakeng sa merero ea meralo, li-splashbacks, lipontšo le tse ling. Li bobebe haholo, 'me li ka bōptjoa ho kopana le litlhaloso tsa mefuta e fapaneng ea likopo tse fapaneng. |

| Mmala | Colored Steel ke titanium e koahetsoeng ka tšepe e sa hloekang. Mebala e fumanoa ka ho sebelisa mokhoa oa PVD derivate. Mefuta e ka holim'a lakane ka 'ngoe e fana ka mefuta e fapaneng ea ho roala, joalo ka li-oxide, nitrides le carbides. |

Litšobotsi tsa Letlapa le Letlapa le Letlapa

Lisebelisoa tse ka sehloohong ke

1. Used bakeng sa ho sebetsana le mefuta eohle ea likarolo tse tloaelehileng le bakeng sa ho hatisa litempe;

2.Used e le likarolo tse phahameng tse nepahetseng tsa mochini oa tšepe;

3. E sebelisoa haholo ts'ebetsong ea phekolo ea mocheso oa khatello ea maikutlo annealing pele e kobeha.

4. E ka sebelisoa e le thepa ea mohaho bakeng sa mohaho oa sechaba.

7. E ka sebelisoa indastering ea likoloi.

8. E ka sebelisoa indastering ea lisebelisoa tsa lapeng. Lekala la matla a nyutlelie. Sebaka le sefofane. Sebaka sa elektronike le motlakase. Indasteri ea mechine ea bongaka. Indasteri ea kaho ea likepe.

Sebopeho sa Lik'hemik'hale sa Tšepe e Tloaelehileng e Stainless

| Kereiti | C | Si | Mn | P | S | Ni | Cr | Mo | Ba bang |

| 304 | ≤0.07 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/10.5 | 17.5/19.5 | ― | N≤0.10 |

| 304H | 0.04/0.10 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/10.5 | 18.0/20.0 | ― | |

| 304L | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/12.0 | 17.5/19.5 | ― | N≤0.10 |

| 304N | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/10.5 | 18.0/20.0 | ― | N:0.10/0.16 |

| 304LN | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/12.0 | 18.0/20.0 | ― | N:0.10/0.16 |

| 309S | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 12.0/15.0 | 22.0/24.0 | ― | |

| 310S | ≤0.08 | ≤1.50 | ≤2.00 | ≤0.045 | ≤0.030 | 19.0/22.0 | 24.0/26.0 | ― | |

| 316 | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | N≤0.10 |

| 316L | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | N≤0.10 |

| 316H | 0.04/0.10 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | |

| 316LN | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | N:0.10/0.16 |

| 317L | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 11.0/15.0 | 18.0/20.0 | 3.0/4.0 | N≤0.10 |

| 317LN | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 11.0/15.0 | 18.0/20.0 | 3.0/4.0 | N:0.10/0.22 |

| 321 | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 9.0/12.0 | 17.0/19.0 | ― | N≤0.10Ti:5ʷʢC+Nʣ/0.70 |

| 347 | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 9.0/13.0 | 17.0/19.0 | ― | Nb:10ʷC/1.00 |

| 904L | ≤0.020 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.035 | 23.0/28.0 | 19.0/23.0 | 4.00/5.00 | N≤0.10Cu:1.0/2.0 |

-

201 304 Mirror Color Sheet Stainless Steel Sheet in S...

-

316L 2B Leqephe la tšepe le sa hloekang le chekiloeng

-

304 Colored Stainless Steel Sheet Etching Plates

-

430 Leqephe la Tšepe le Perforated

-

SUS304 Leqephe la Tšepe le Khabisitsoeng

-

201 J1 J3 J5 Leqephe la Tšepe e Hloekileng

-

Maqephe a Tšepe a Perforated

-

Leqephe la tšepe la PVD 316 le mebala-bala

-

SUS304 BA Stainless Steel Sheets Molemo ka ho Fetisisa

-

SUS316 BA 2B Stainless Steel Sheets Supplier